Best Practice of AI in Predictive Maintenance

Manufacturing and many other industries benefits greatly from AI and predictive maintenance. Rather of reacting to issues as they arise, predictive maintenance works to prevent them from occuring in the first place.

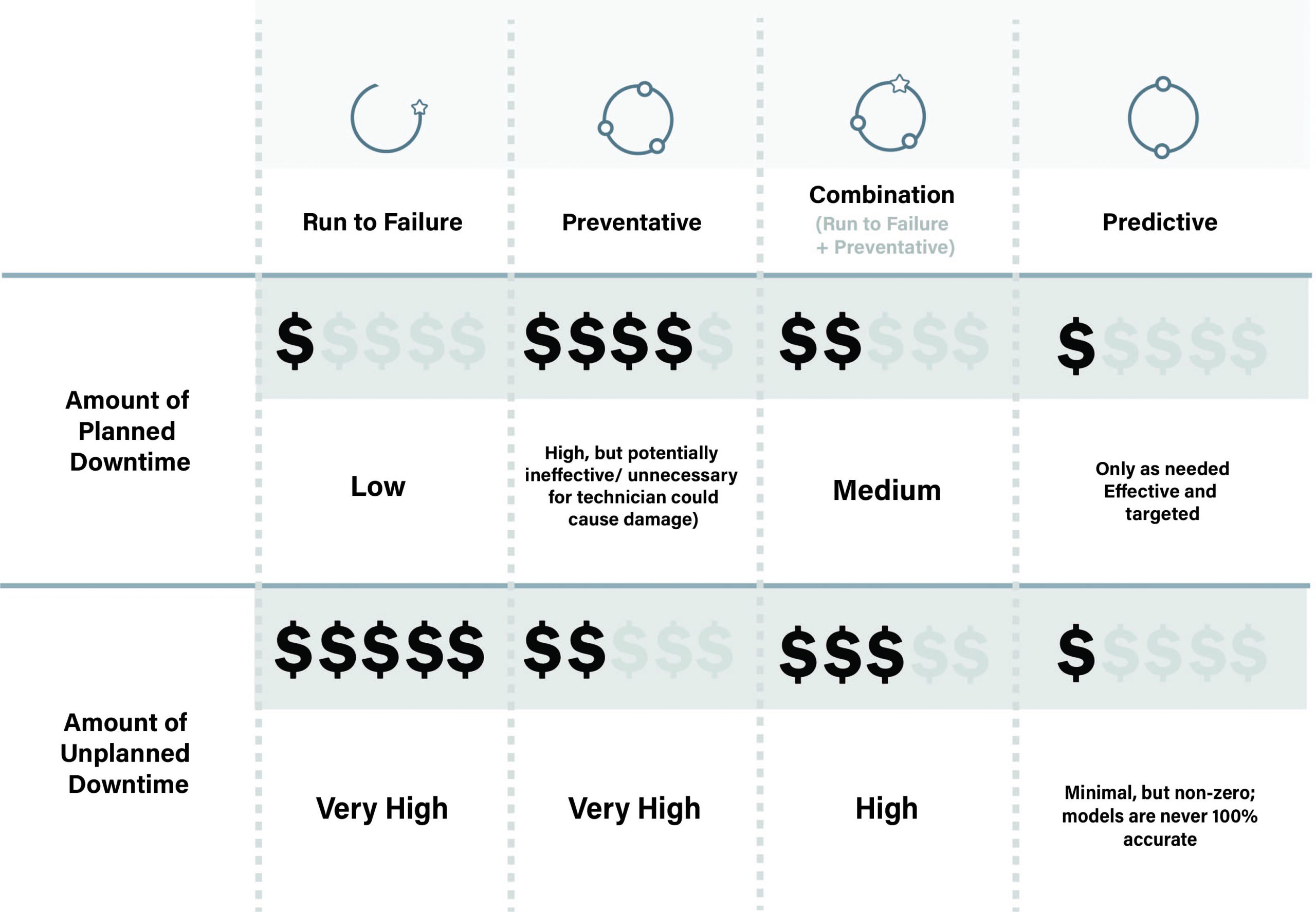

Low maintenance expenditure leads to excessively high repair costs and downtimes when equipment fails via run-to-failure procedures. The objective of predictive maintenance is to be able to make prediction when equipment will occur to fail (depending on a variety of criteria) and then avoid the failure through regularly scheduled and corrective maintenance. Advantage of predictive maintenance reduces both excessive repair costs and time spent on maintenance that isn’t necessary.

When comparing predictive maintenance to other equipment maintenance approaches, the advantages of this strategy are totally clear. Low maintenance expenditure leads to excessively high repair costs and downtimes when equipment fails via run-to-failure procedures.

Image Source: Dataiku

Knowing when something goes wrong isn’t enough. Predictive maintenance allows companies to utilise complex algorithms and machine learning to gain valuable insights into the equipment’s lifetime. Rather of reacting to issues as they arise, predictive maintenance allows you to prevent them from occurring in the

first place.

Predictive maintenance reduces both excessive repair costs and time spent on maintenance that isn’t necessary. While models aren’t perfect, they do provide the ability to make maintenance decisions based on historical patterns and real-time data, which adds a whole new level of cost savings.

Our Offerings

RDA’s Data Science Team offer benefits to you from our predictive maintenance solutions:

- Robust machine learning end-to-end workflows.

- We ensure robust model monitoring within the platform to prevent from model drifting

- We ensure machine learning benefits across industries value chain use cases